Adhesive Films

You’re stuck with us!

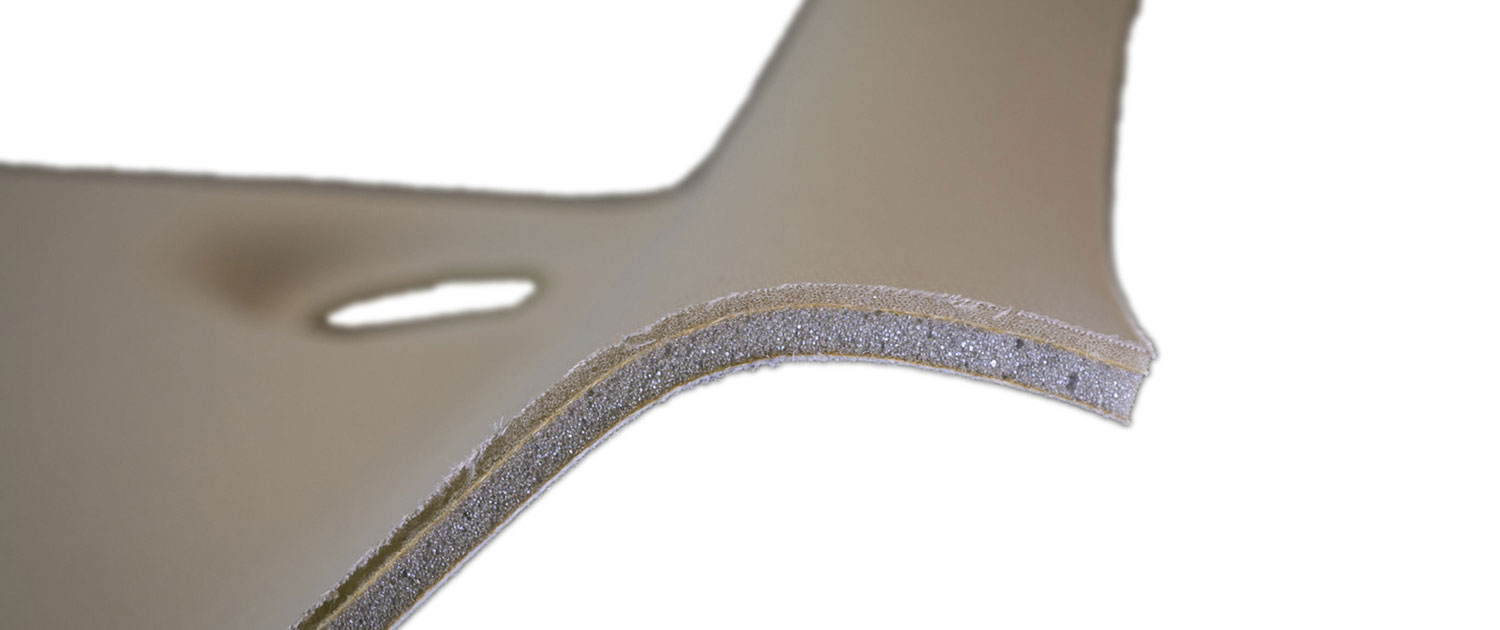

Adhesive Films are thermoplastic films that are used to bond similar and dissimilar materials together. Heat activated, these films are non-tacky and can withstand normal warehouse conditions. As opposed to glues, they are easily handled and can bond a wide range of substrates together. These films can be mono layer or co-extruded with activation ranges from 85°C to 220°C.

Advance Packaging supplies films that custom manufactured for adhering to many different substrates from closed cell urethane foam to shoddy pads or non-wovens. We can design the films to have adhesives for different substrates on either side of the film. We can also provide a wide variety of thermal melt points and barriers. Advance has all the SDS sheets, Spec Sheets, PPAP’s and COA’s for your application.

Give us a call to discuss your application.

Extrusion Capabilities:

- Mono to 9 layer Co-extrusions

- Cast or Blown

- 1″ to 100″ Wide

- .001″ to .020″ Thick

- Clear and Colors

- Embossed or Plain

Layer Capabilities:

- 85°C seal initiation point and greater

- Thermal barriers up to 220°C

- Adhesive layers from 10 -100% of the structure

- Perforations available

Bonds to:

- Shoddy pads

- Urethane

- Fabric

- Closed Cell Urethane Foam

- Open Cell Foam

- Extruded EVA

Automotive Uses:

- Headliners

- Floor Systems

- Dash assemblies

- Package Trays

- Seat assemblies

- Trunks

- Decks

- Door Panels